316L Stainless Steel Filters – Custom-built, high specification, simple and easy to maintain

Product News Wednesday, December 9, 2015: Axium Process Ltd

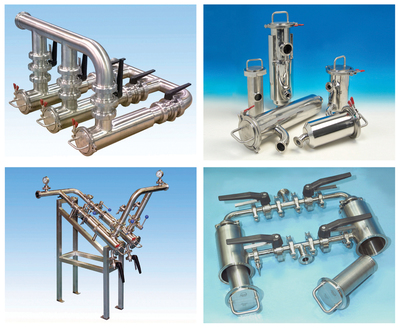

Axium Process, filtration specialists, manufacture a comprehensive range of 316L stainless steel filters which are renowned for their robust construction, versatility, reliability and their ease and simplicity to maintain. The filters, which are manufactured to hygienic standards in accordance with ASME-BPE principles, are available with full materials certification, wedge-wire or sintered mesh elements and are designed for filtration levels from 5 micron up to 6000 micron as standard.

Widely used across a broad range of industries for a diverse range of duties, Axium’s Standard range of filters include a 90º, in-line and straight through options as well as a Compact filter version designed for use in confined areas or where flow rates are low.

Axium’s engineers specialise in customised hygienic stainless steel fabrication and filters are routinely manufactured to suit customer requirements. Engineers work closely with customers to fully understand their processing requirements so that the optimum filter is supplied for a given application. Customised options include stand-alone, duplex, triplex, multiplex, large capacity and jacketed filters. Sample valves, drain or vent valves can be integrated into any of the options as can isolation or back flush valves if required.