Contact Details:

Power Jacks Ltd

Balmacassie Commercial Park

Ellon

Aberdeenshire

AB41 8BX

United Kingdom

Tel: +44 1358 285100

Fax: +44 1358 724105

Send Enquiry | Company Information

Special Actuators for Nuclear Core Inspection Machine

Product News Thursday, August 13, 2009: Power Jacks Ltd

Reactor core inspections of nuclear reactors is an essential function of operating a nuclear power station that must achieve the highest quality to ensure continued power supply with the best plant safety and efficiency. A key part of the maintenance program is the inspection of the nuclear reactor cores. To perform this operation a specialist machine with TV inspection and bore measuring is used. The machine is lowered to engage with the reactor standpipes by an electric linear actuator supplied by Power Jacks.

The machine is called the NICIE (New In-Core Inspection Equipment). It was developed by BNS Nuclear Services with whom Power Jacks worked in close partnership to design and manufacture the main linear actuation unit engaging the machine with the reactor standpipe. Four additional jacks act as stabilisers when the machine is coupled to the standpipe.

The NICIE inspects nuclear reactors by lowering a camera down into the reactor fuel channel to provide measurement and maintenance checks. The main body of the machine is raised and lowered to engage it with the reactor stand pipes. A specially designed electric linear actuator from Power Jacks performs this actuation.

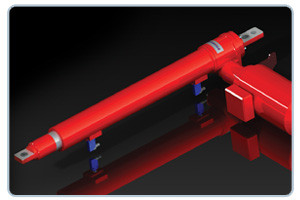

The actuator is designed to lift and lower the 20kN load over a stroke of 525mm with the end of travel signalled by proximity sensors installed in the actuator. To maintain a rigid column over the stroke the actuator has two internal guidance mechanisms for the ram. As a safety feature the ram is fitted with a proprietary clutch to act, as a mechanical fail safe, to prevent an overload condition should external control systems fail. Powering the actuator is a 0.75kW motor with integral brake for position holding and an auxiliary hand drive shaft should manual operation be required. The machine itself is mounted on wheels for easy transportation however when positioned for use four screw jacks at the base of the machine take the weight off the wheels similar to stabiliser jacks on mobile cranes.

Hinckley Point Power Station will be operating the hoist, currently being tested by BNS Nuclear Services at Whetstone in England. Hinkley Point is a nuclear power station near Bridgwater, Somerset, on the Bristol Channel coast of south west England. It is an Advanced Gas-cooled Reactor (AGR), which was designed to generate 1250 MW of electricity.

Power Jacks has a long standing working relationship of over 38 years with BNS Nuclear Services, now operating under the Babcock Group. Alex MacMillan, Leading Design Engineer, of BNS Nuclear Services, said that the products from Power Jacks for the NICIE hoist were delivered on time and on budget and are now fitted to the first of two machines.

Frank Shinn, Power Jacks Area Sales Manager for the East Midlands says: ”This is a typical application from BNS Nuclear Services - two of our products on one machine, one of which has been engineered specifically to suit, the other is a standard unit. ... as usual the selection process was an enjoyable and interesting experience, dealing with engineers who are specialists in the business”.

Power Jacks expertise in providing an engineered solution for a customers linear actuation application continues to meet the exacting requirements of the nuclear industry whether at the stage of development, de-commissioning or new build.